I’ve sort of agonized over how to set up a boom preventer/controller. Like everything else, I’ve done a pile of reading on boom preventers, boom brakes, etc. I was never interested in a boom brake. Those devices don’t allow me to manually control the boom the way I would like to. Plus, I have better uses for the sums of money that those things command. Additionally, why would I pay someone for a device, when I can make my own system?

I kind of had an idea of how I wanted the boom preventer lines set up. I began doing some reading to make sure that other people had similar ideas and to see if there were any problems that other sailors had encountered that I wasn’t considering.

Our main sheet is attached to a boom bail about 2/3 of the way down the boom. I figured that would be the easiest point to attach the preventer lines. In my reading I found that there are mid-boom preventers and end-boom preventers. Apparently, both can snap your boom in two. Moral of the stories, they will both work. The choice of which one just depends on how one decides to set up their system. My intended set up would be a mid-boom preventer. Looking good so far.

Mocked up preventer line on the boom bail. It’s the one with the bowline tied in it. The real line will be 3/8″.

The next thing was to decide where the lines would run to before turning back and heading to the cockpit. The easiest thing would be to put an additional block on the t-tracks on the toe rails. The main issue with this on Emet is that the tracks don’t run far enough forward. Good, because I didn’t want to have to go under or over a line that was crossing the deck waist high. I could possibly run the lines to the bow and connect to one or more of the cleats and then turn the line back to run to the cockpit. I really want to keep the deck clear of lines. Lines on deck will roll when stepped on and I would prefer to not have that happen while healed over in 20 knots and I’m trying to go forward to put in a reef. Not really an option as far as I’m concerned. That means that I would need to have the lines run to a point on the cabin top and then turn back and run to the cockpit.

Here is the preventer line on the starboard side mocked up. I have it running down to the boat hook, which I have held in place with some clamps. It then runs parallel with the main sheet back into the cockpit.

Easy enough for the starboard side because the main sheet runs through a 2 inch hole in the coaming above the companionway hatch. The port side had no such hole. I was kind of nervous about drilling a 2 inch hole into it.

Starboard side coaming hole. This will be the final configuration on the starboard side allowing the boom preventer and main sheet to be tightened and tied off.

The project languished for over a year. I kept mocking it up, measuring, and then researching more to see if there were other ideas. The hole man, the hole. I just couldn’t bring myself to drill that hole.

Finally, I pulled the trigger. I went to the hardware store and purchased a 2.125″ bi-metal hole saw. I had the hole position all marked out and just set about drilling resolving that I would figure out any problems as they arose instead of trying to anticipate everyone. Sometimes . . . the best way to get in cold water is to just jump in.

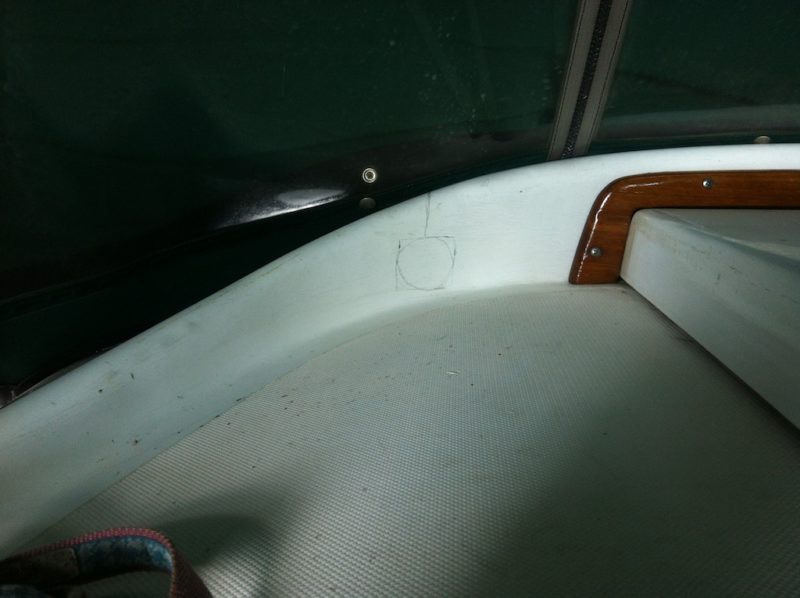

Hole started. You can see on the left that I had mocked up and run the preventer line back to the cockpit on the port side to make sure I had everything positioned correctly.

Almost through. I used a hammer and chisel to clear away fiberglass as needed to allow the hole saw to continue to drill deeper.

Checking the other side. I had to remove the lower right button snap. In the end I removed both because neither one is used.

Now I just need to gelcoat the fiberglass on the inside of the hole. I was completely surprised that the coaming was 100% fiberglass. Old boat builders, gotta love ’em.

[…] drilling the hole, the next thing that I had to do was install the padeyes that would hold the blocks to turn the […]