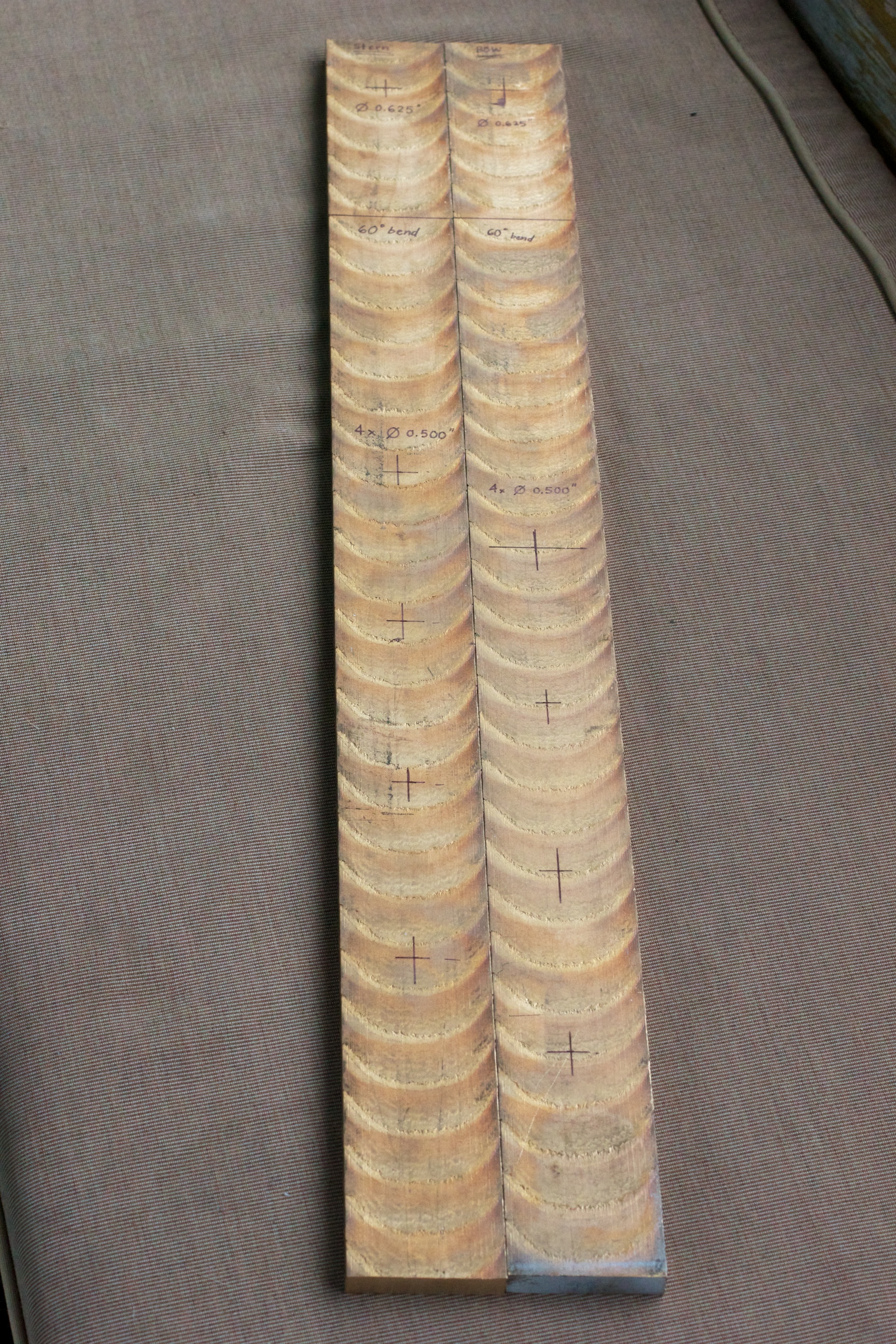

So, I received the aluminum bronze plates. The next step was to find someone willing to do some work on them for a reasonable price. I got in the car and started driving down highway 6. I stopped at the first “machine shop” that I saw: H&H Machining. I walked in and the owner, Fred, was super nice and helpful. I gave him the basic idea of what I needed done.

“We can certainly try to bend that for you, but, in the past, anytime we’ve tried to bend this kind of brass this much, it’s snapped.”

Yikes. I thought, this is bronze not brass. “Well, from what I’ve read, you’ve got to heat it up.”

“Yep, we heat it up. And it sometimes still snaps.”

“Well, about how much would you charge to do this work?”

“We charge $50 an hour.”

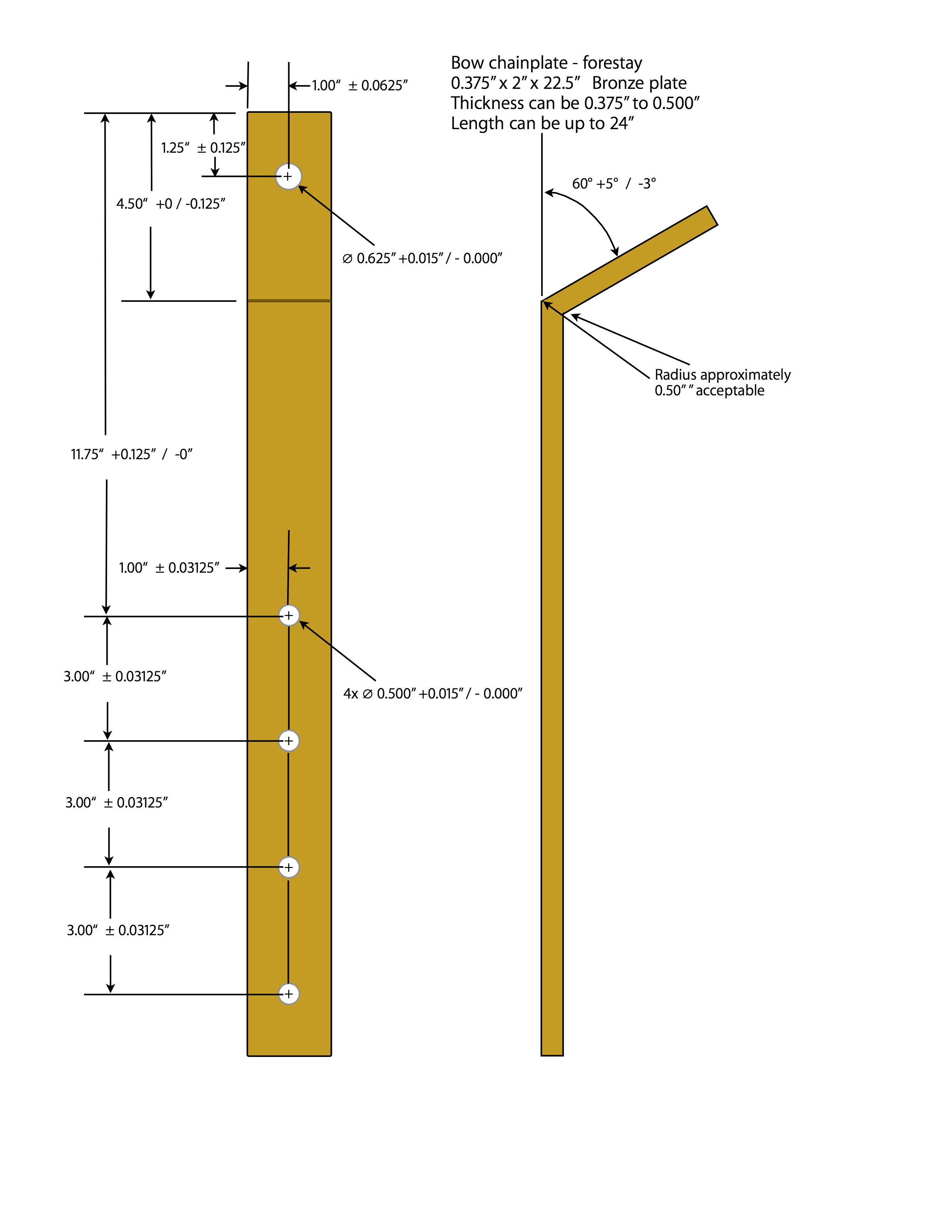

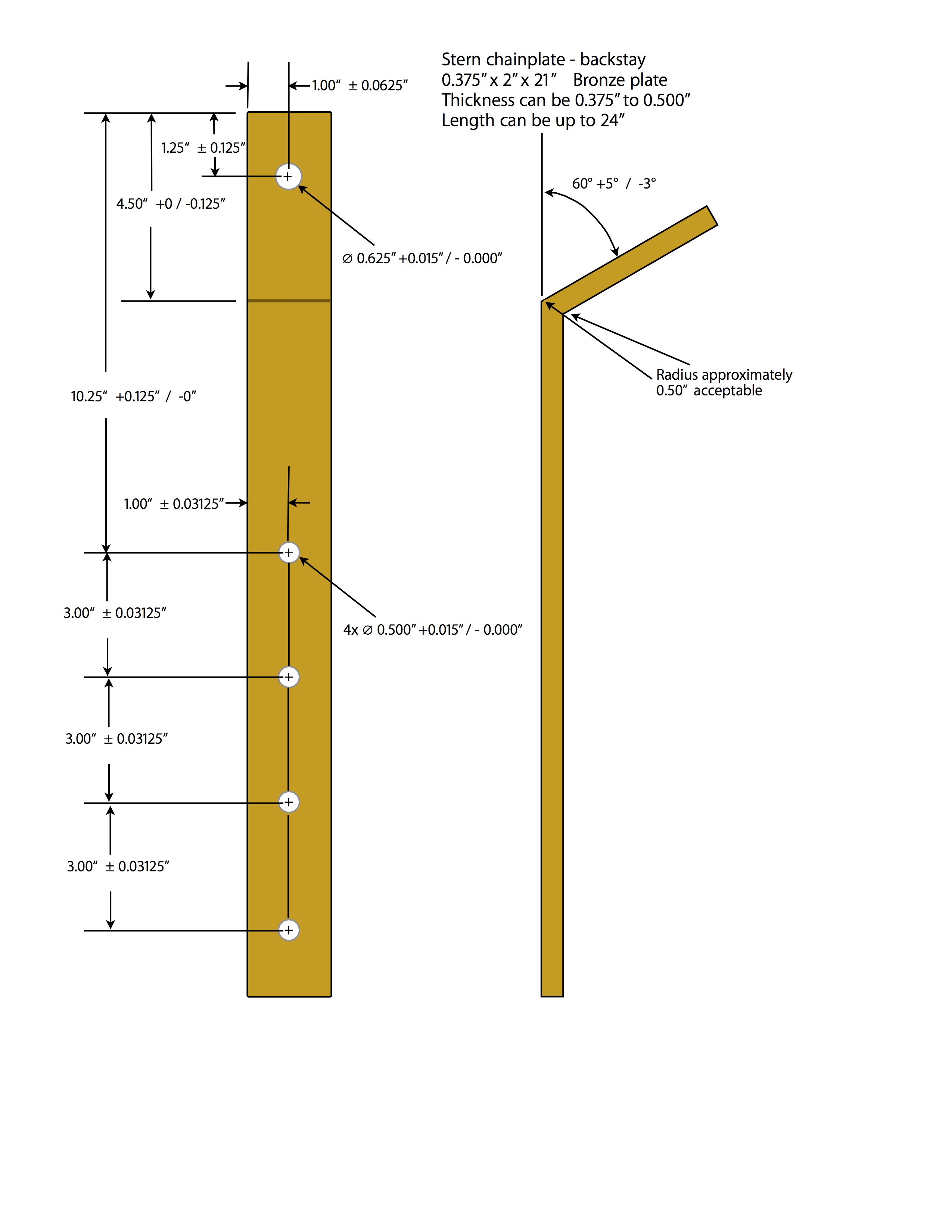

“Perfect. I’ll make up some drawings, mark up the bars for you, and bring them back.”

So, that’s what I did.

I took the drawings and bars to the shop, Fred said he’d call when he had them done and with a handshake off I went, hopeful.

Two days later, Fred called. He said that one of the bars they were able to bend, but it cracked. And the other snapped in two pieces when they bent it. He told me to call Farmers Copper and get some bendable bronze from them. So, I gave Farmers Copper a call and spoke with Rob. He said to send over the drawings and he would quote prices for me. I did that and he came back with $300 for both pieces shaped and drilled in C655 silicon bronze. I told Rob to go ahead.

I went and paid Fred for his company’s time and picked up the two, make that three, pieces.

Just waiting now for the new silicon bronze pieces to be ready. I still have to do some reinforcing at the bow since the chain plate will no longer be an integral part of the bow roller. That should be some fun epoxy/glass work in the chain locker.

The lesson from all this is the C954 aluminum bronze is slightly bendable. Maybe up to 15 degrees. Anything more than that and I suppose C655 silicon bronze is the way to go.

I might still be able to use that bronze for something. Maybe for backer plates on the chain plates.

[…] Read Part 1 Read Part 2 […]