I believe that 3M 5200 really has no place on a boat. Or at least I did. The stuff has a tenacious grip once cured and there are practically zero things on a sailboat that are “permanently” mounted. Anything that is to be permanent on Emet is installed with fiberglass and epoxy.

We just recently finished installing a new forestay chainplate (long post coming). It was bedded down with butyl tape. When we were raising the headsail on our roller furler, we weren’t paying careful enough attention and the sail luff got ripped as it was being pulled into the luff groove. It wasn’t too bad, but a repair was required.

So, I ordered some sail repair gear: sewing palm, needles, twine, wax. These items were on the list to purchase. This tear just accelerated the time frame. We got a big sheet of dacron from a friend that had a ginormous sail that he was parting out. Then I went searching for the best way to repair it.

And I found this: http://www.cruisingworld.com/stitch-time

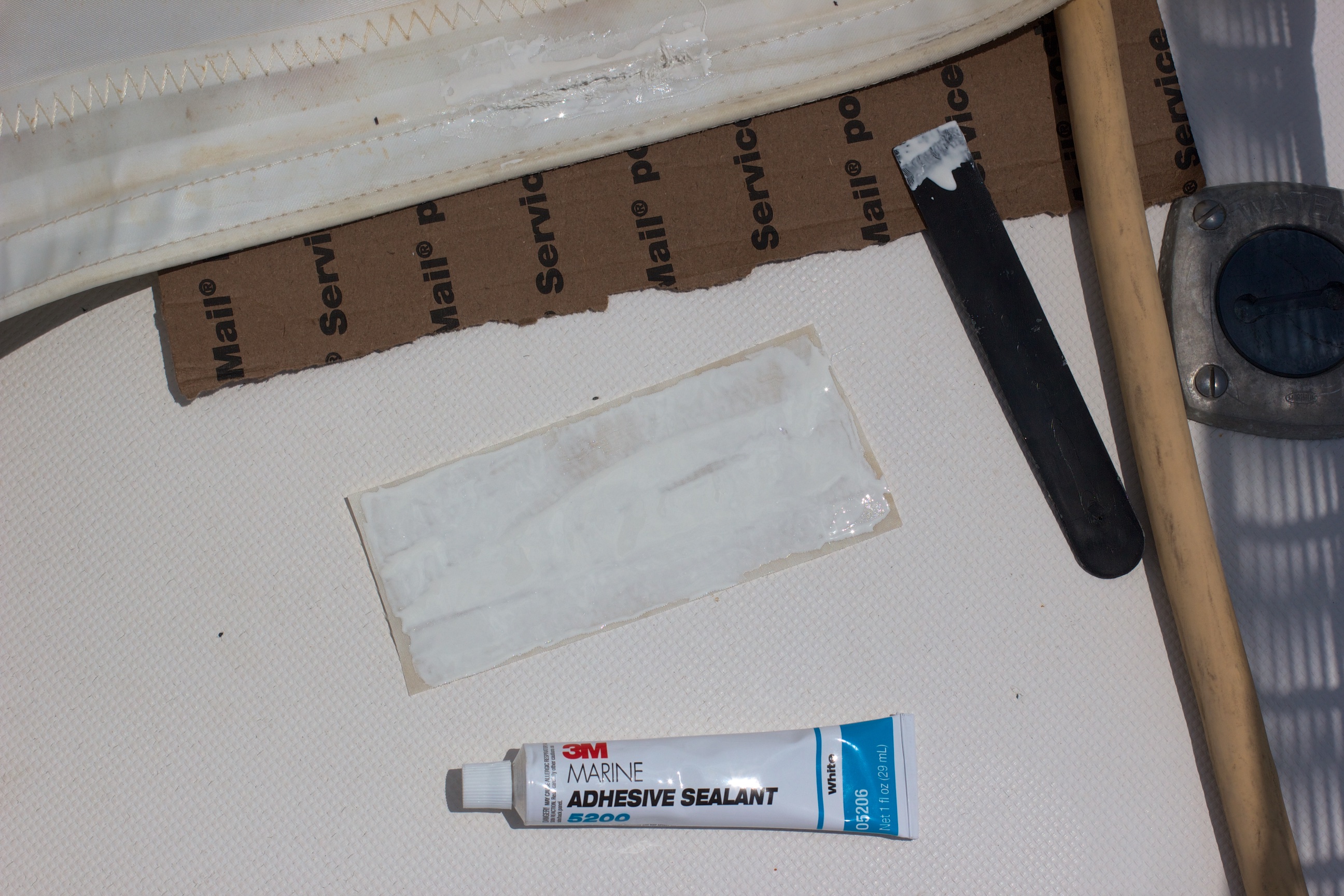

5200 used for sail repair.

I had a tube of it that was to be used to fill a hole in the mast where the old radio direction finder cable entered. I stuck a piece of Gorilla tape over it as a temporary remedy and it has become permanent, so the 5200 was just begging to be used. It wasn’t fast cure, but I figured it would work.

The rip.

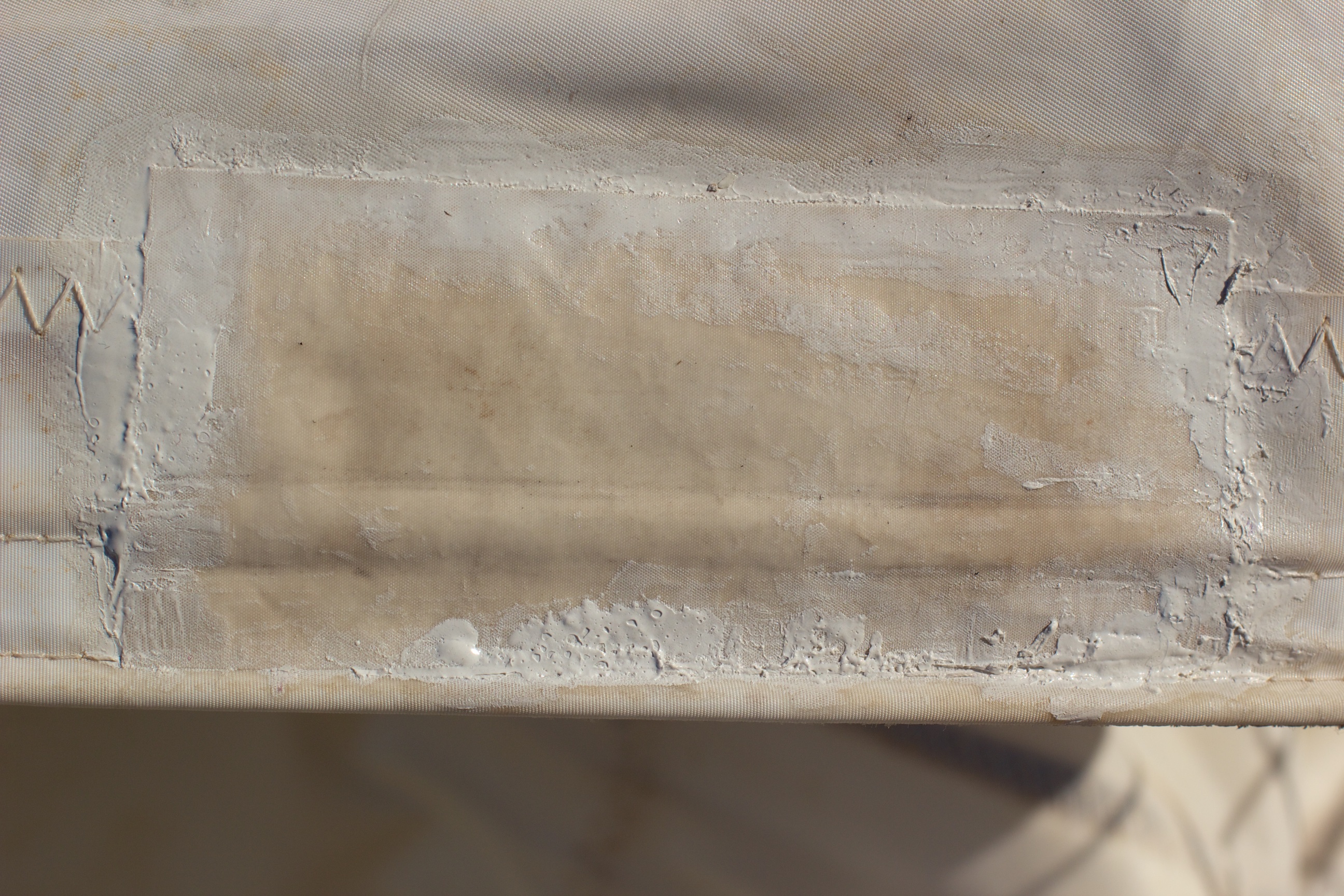

The 5200 applied to the patch and sail.

Because the patch went over a second bolt rope, it wouldn’t sit flat. I used some plastic wrap and clothespins to keep the patch pressed against the sail.

Here a piece of bronze is used to weigh the patch down on the other side of the bolt rope.

And the finished repair. Not very pretty, but I’ll take ugly and strong over pretty and weak any day. I pulled the plastic wrap off after about 6 hours so that it wouldn’t become a part of the sail.

Only time will tell if the fix holds. I have no reason to think that it won’t. 5200 is dang near permanent and it’s flexible enough to bend and twist with the sail.

This morning I raised the headsail with no problems at all. The patch slid right into the luff groove of the furler and went all the way up.