Emet’s breaker panel is in pretty sad shape. It’s original equipment and shows. I had priced out getting a brand new one, but it was upwards of $1300. That fancy one featured above is over $2000 which is a little more than the cost of the CPT Autopilot. YIKES!! But, it sure is pretty.

There’s nothing wrong with the current switches/circuit breakers. They all work great. It’s the panels themselves. They are plastic and starting to deteriorate badly and let’s face it, they just look old. There are numerous pieces that are broken off as the plastic has degraded over the years and become extremely brittle. It’s still definitely workable and at the same time probably needs to be replaced if possible.

I had purchased a piece of aluminum from Speedy Metals with the intention of making one myself. Instead of having 3 small panels, I was going to create one big one that would be hinged at the bottom and locked at the top so that it folds down. It’s just a matter of drilling a bunch of holes. As I don’t have an NC drill press, this meant that I was going to have to be precise about marking the sheet and then center punching the holes. I was also going to have to purchase a 0.620 drill bit. Maybe 0.625 would have worked.

A concern was that the aluminum would probably start to corrode. I had planned on polishing the ever loving crap out of it in the hopes that I could get a glass mirror finish on both sides which would help to prevent corrosion. Essentially, a mirror finish exponentially reduces the surface area thus decreasing the opportunity for aluminum to combine with oxygen.

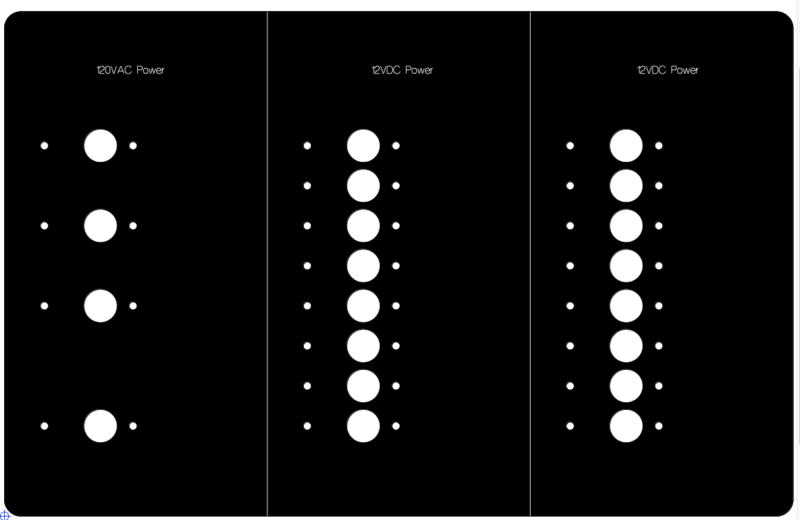

And then I happened to find Front Panel Express. Pretty awesome, in theory. They provide essentially a CAD/CAM program (Front Panel Designer) where you design your panel, get it priced right in the program, and order it. Here’s the panel I designed in about an hour.

The small holes are countersunk on the old panel, but if I add countersinks to each one, they become $1.52 each instead of $0.25 each. That’s what is cool about their program: you can add and subtract design characteristics and immediately see the price difference. The black anodized panel that you see above, without countersunk holes, is $89.65 less shipping. If I remove those 2 dividing lines, the price drops to $84.43.

I can make labels for each breaker using printable vinyl sheets. One could, of course, have each breaker labeled by paying to have the panel itself engraved. That would make this one that much more expensive and also limits the flexibility of reassigning the breaker to another task, which you can clearly see happens just by looking at the original with different types of “temporary” labels.

I haven’t decided if I want to shell out the money to have one made or just go with the original plan of attempting it myself. I sure like the idea of having it done professionally.